As a plastic part design for injection molding, we have vast knowledge base allows us to provide one-stop service including: product design,materials selection,prototyping,mold design,injection mold making,injection molding, LOGO printing,related parts sourcing, packing material sourcing,assembly,packing as well as door to door delivery.

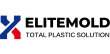

| Shaping Mode | Plastic Injection Mould |

| Place of Origin | Guangdong, China |

| Model Number | customized plastic injection mold mold-G21456 |

| Product Material | Plastic |

| Product | Scanners mold |

| Product Name | Plastic injection mould |

| Mold material | P20/718/738/NAK80/S136 |

| Material | PMMA/ABS/PE/PC/PVC/POMPS/PP/PET/PA |

| Design software | CAD/PROE/UG/3D/DWG/IGS/STEP/PDF/JPG |

| Cavity | Multi Cavity moulds |

| Mould life | 259094shots |

| Runner | Cold Runner. Hot Runner: Yudo |

| Surface treatment | Polish. Etched. Texture |

| Certification | ISO9001:2015 |

| Size |

77 * 53 * 48 OEM/ODM/Customization |

| Packaging Details |

1. injection mold: by pallet or as buyer’s request. 2. injection parts: by bags then export carton, or as buyer’s request. |

| Port | Shenzhen |

| Supply Ability |

20000 Piece/Pieces per Day Please contact the us to check the exact delivery time |

| Samples |

Maximum order quantity: 1000 piece Sample price: $150/piece Please contact us to confirmation |

Custom Injection Molds

plastic part design for injection molding Material Selection

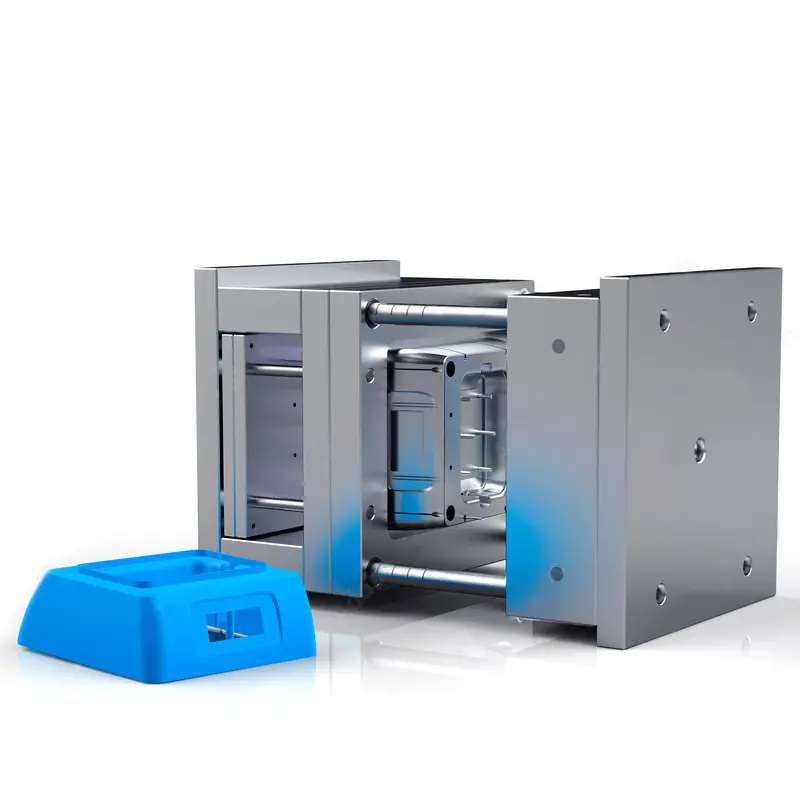

plastic part design for injection molding Prdduction Process

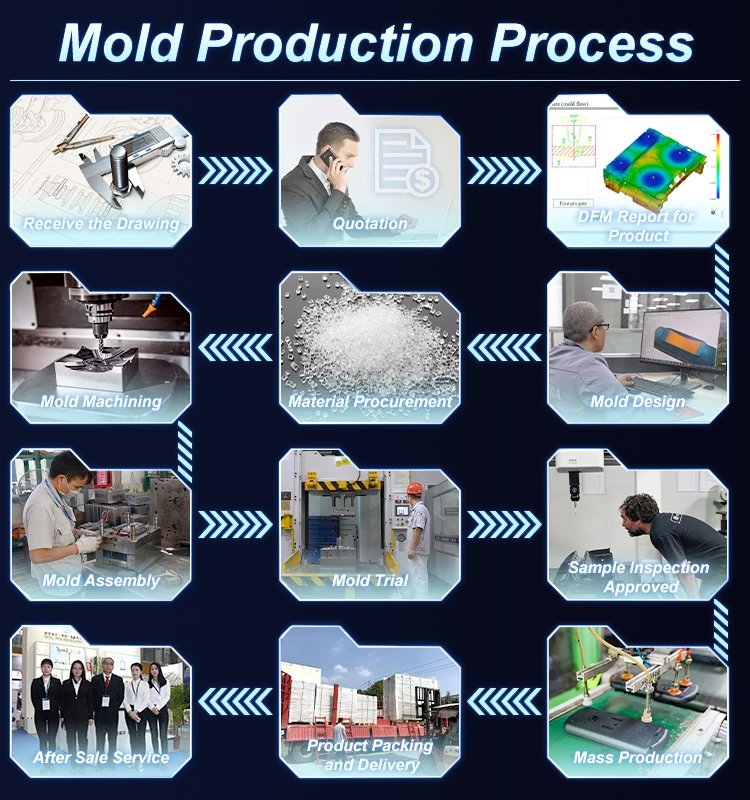

3D Injection Molding Machine

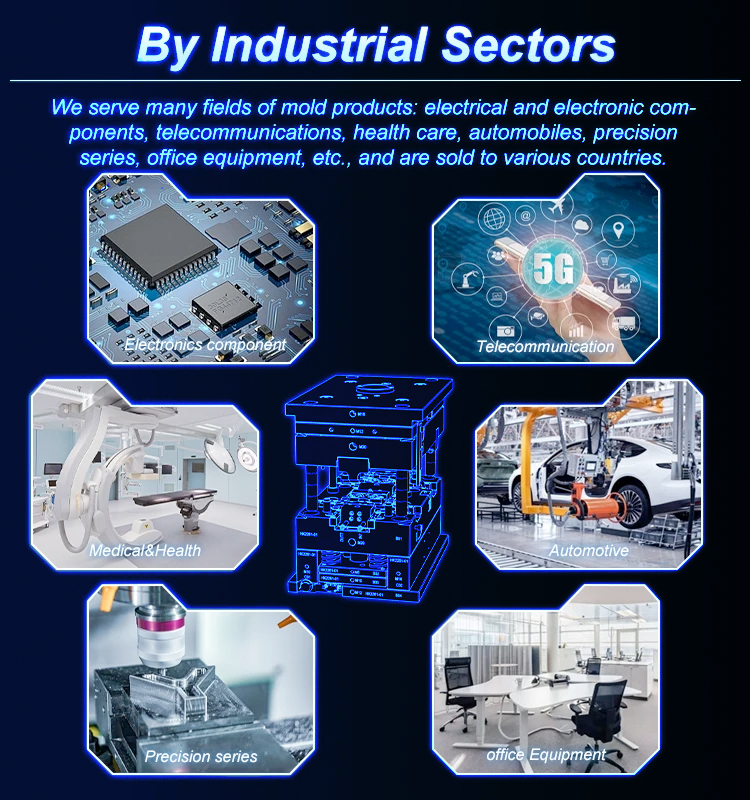

By Industrial Sectors

Elite mold as one of the most professional plastic part design for injection molding manufacturers has the advantages at:

All our products are strictly according to ISO/SGS regulations, with affordable prices with unparalleled quality.

We take care of our product quality, any defect of the goods, we will take responsibility. You are risk-free.

Big production capacity makes short lead time 7 – 20 days, depending on the complexity of the product.

OEM/ODM service is available.

Low MOQ, we can accept low MOQ as 180 sets, or even less quantity for every single item in big production order.

We have full experience in exporting and project management, to secure your order 100%.

With 15 years of experience in the plastic injection mould industry, we have full experience in customized product development. And we have quite some top-rated products to meet your market requirement.

Full range of injection molding plastic parts,plastic parts produced by an injection-molding operation and accessories, to meet customer’s different needs.